Table of Contents

What is an RC Car Axle Bearing?

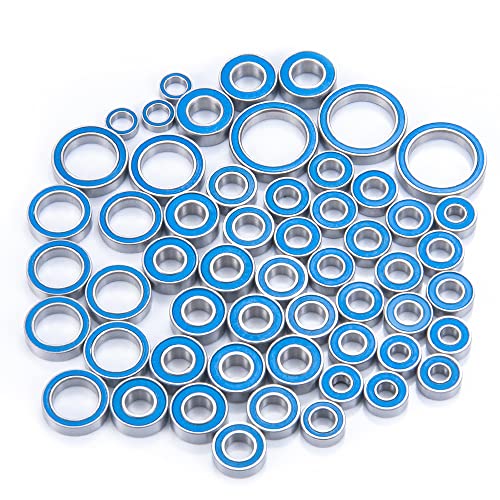

When it comes to RC (Remote Control) cars, one of the most critical components is the axle bearing. An RC car axle bearing is a small but significant part that allows the wheels to rotate smoothly, ensuring optimal performance and handling. These bearings are typically made of durable materials such as steel or ceramic and come in various sizes and styles to fit different types of RC cars.

Why Are RC Car Axle Bearings Important?

RC car axle bearings play a crucial role in the overall performance and durability of the vehicle. Here are a few reasons why they are so important:

1. Reduced Friction: Axle bearings significantly reduce friction between the rotating wheel axle and the stationary parts of the RC car. By minimizing friction, these bearings improve the efficiency of the car’s drivetrain and reduce wear and tear on the components.

2. Smooth Rotation: The smooth rotation of the wheels is essential for precise control and handling of an RC car. Axle bearings allow the wheels to spin smoothly, enabling the car to navigate corners, jumps, and obstacles with ease.

3. Increased Durability: High-quality RC car axle bearings are built to withstand the demands of intense RC car racing and off-road adventures. They are designed to handle the high speeds, impacts, and vibrations associated with RC car activities, ensuring the longevity of your vehicle.

4. Improved Performance: By reducing friction and enabling smooth rotation, axle bearings contribute to improved overall performance. RC cars equipped with high-quality bearings experience enhanced speed, acceleration, and responsiveness, giving you a competitive edge on the track.

Choosing the Right RC Car Axle Bearings

Now that we understand the importance of RC car axle bearings, let’s look at some factors to consider when selecting the right bearings for your RC car:

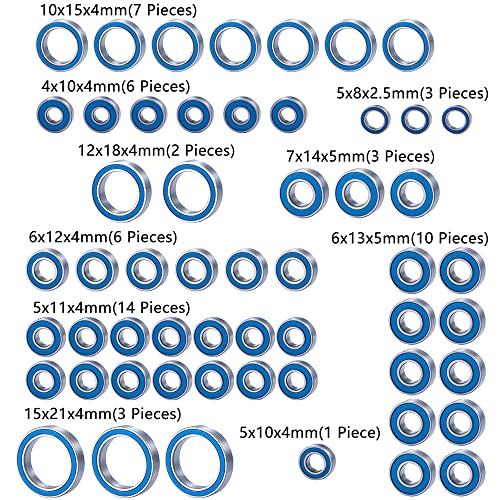

1. Size: Make sure to choose axle bearings that are compatible with the specific size and dimensions of your RC car’s wheels. Consult the manufacturer’s specifications or refer to the user manual for the correct sizing information.

2. Material: RC car axle bearings are available in different materials, such as steel or ceramic. Steel bearings are more cost-effective and suitable for general RC car enthusiasts. However, ceramic bearings offer superior performance, with reduced friction and increased durability, albeit at a higher price point.

3. Sealed or Shielded: Consider whether you prefer sealed or shielded axle bearings. Sealed bearings provide better protection against dirt, debris, and moisture, making them ideal for off-road RC car applications. On the other hand, shielded bearings allow for easier maintenance and cleaning.

4. Brand Reputation: Opt for well-known, reputable brands when purchasing RC car axle bearings. Brand reputation often reflects product quality, performance, and customer satisfaction. Read reviews and seek recommendations from fellow RC car enthusiasts to ensure you choose a reliable brand.

Installing RC Car Axle Bearings

The installation of RC car axle bearings may vary depending on the specific model and design of your RC car. However, here are some general steps to guide you through the installation process:

1. Prepare the Car: Turn off the RC car and remove the wheels from the axles. Use a wrench or a socket to loosen and remove any retaining nuts or bolts.

2. Remove Old Bearings: Carefully remove the old bearings from the wheel hub using specialized tools such as bearing pullers or pliers. Take note of their orientation for proper placement of the new bearings.

3. Clean the Wheel Hub: Before installing the new axle bearings, make sure to clean the wheel hub thoroughly. Remove any dirt, grease, or debris to ensure a smooth fit and optimal performance of the new bearings.

4. Install New Bearings: Place the new axle bearings into the wheel hub, aligning them according to the orientation of the old bearings. Gently press or tap the bearings into position using suitable tools or a small mallet.

5. Reassemble the Wheels: Once the new bearings are installed, reattach the wheels to the axles and secure them with the retaining nuts or bolts. Ensure that the wheels spin freely and smoothly without any wobble or resistance.

6. Maintenance: Regularly clean and lubricate your RC car axle bearings to maintain their performance and prolong their lifespan. Use a suitable bearing lubricant recommended by the manufacturer for optimal results.

Conclusion

In summary, RC car axle bearings are a vital component that plays a crucial role in the performance and durability of your RC car. These bearings reduce friction, enable smooth rotation, and improve overall handling and control. Choosing the right axle bearings, installing them correctly, and performing regular maintenance will ensure optimal performance and longevity for your RC car. Upgrade your RC car’s axle bearings today and experience the difference it makes on the track or off-road!

Frequently Asked Questions (FAQs)

1. Can I use the same size axle bearings for all RC cars?

No, different RC cars may have varying wheel sizes and dimensions, requiring specific axle bearing sizes. Always refer to the manufacturer’s specifications or user manual for the correct sizing information.

2. Are ceramic axle bearings worth the higher price?

Ceramic axle bearings offer improved performance with reduced friction and increased durability. If you prioritize enhanced performance, the higher price of ceramic bearings may be worth it.

3. Do axle bearings require regular maintenance?

Yes, regular maintenance is recommended for RC car axle bearings. Cleaning and lubricating them periodically will ensure optimal performance and extend their lifespan.

4. Can I install axle bearings myself?

Yes, installing axle bearings can typically be done by RC car enthusiasts. However, if you’re unsure or uncomfortable with the process, it’s best to seek assistance from a knowledgeable RC car mechanic or hobby shop.

5. How often should I replace axle bearings?

The lifespan of axle bearings varies depending on various factors such as usage, operating conditions, and maintenance. Inspect them regularly for signs of wear and replace them if they show significant damage or decreased performance.

Price: $25.99

(as of Jul 13, 2023 21:06:21 UTC – Details)